Nothing beats ultrasound for tube rolling plants

The Lut 2.0 brings ultrasound performance to online hot wall thickness measurement with 10µm precision. Its integrated OD gauge adds full dimensioning of tubes and pipes.

Talk to an expertGet the Lut 2.0 advantage

Accurate, true wall thickness

Advantages of laser-ultrasonic technology over radiometric gauges:

- Direct, true wall thickness measurements

- Higher outer diameter range available

- Accuracy unaffected by environment, such as water, dirt, dust and vibration

- No need for continuous recalibration

- Captures all critical tube characteristics and features.

Direct eccentricity measurement

Laser ultrasonics is the only online technology that can directly detect and quantify eccentricity. The Lut 2.0 software automatically detects and monitors eccentricity sources, such as unevenly heated billets, incorrect piercing mill settings, plug wear, etc.

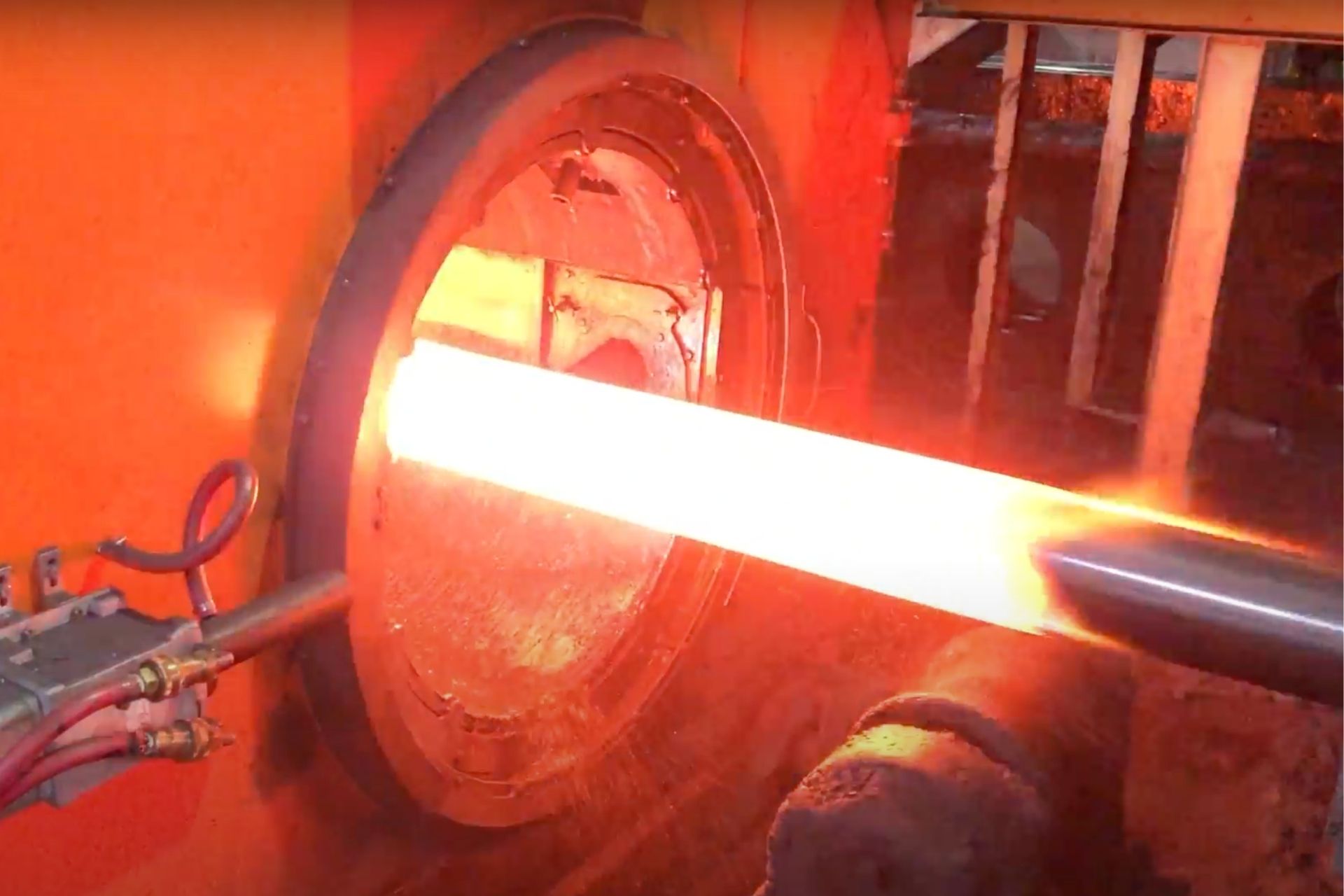

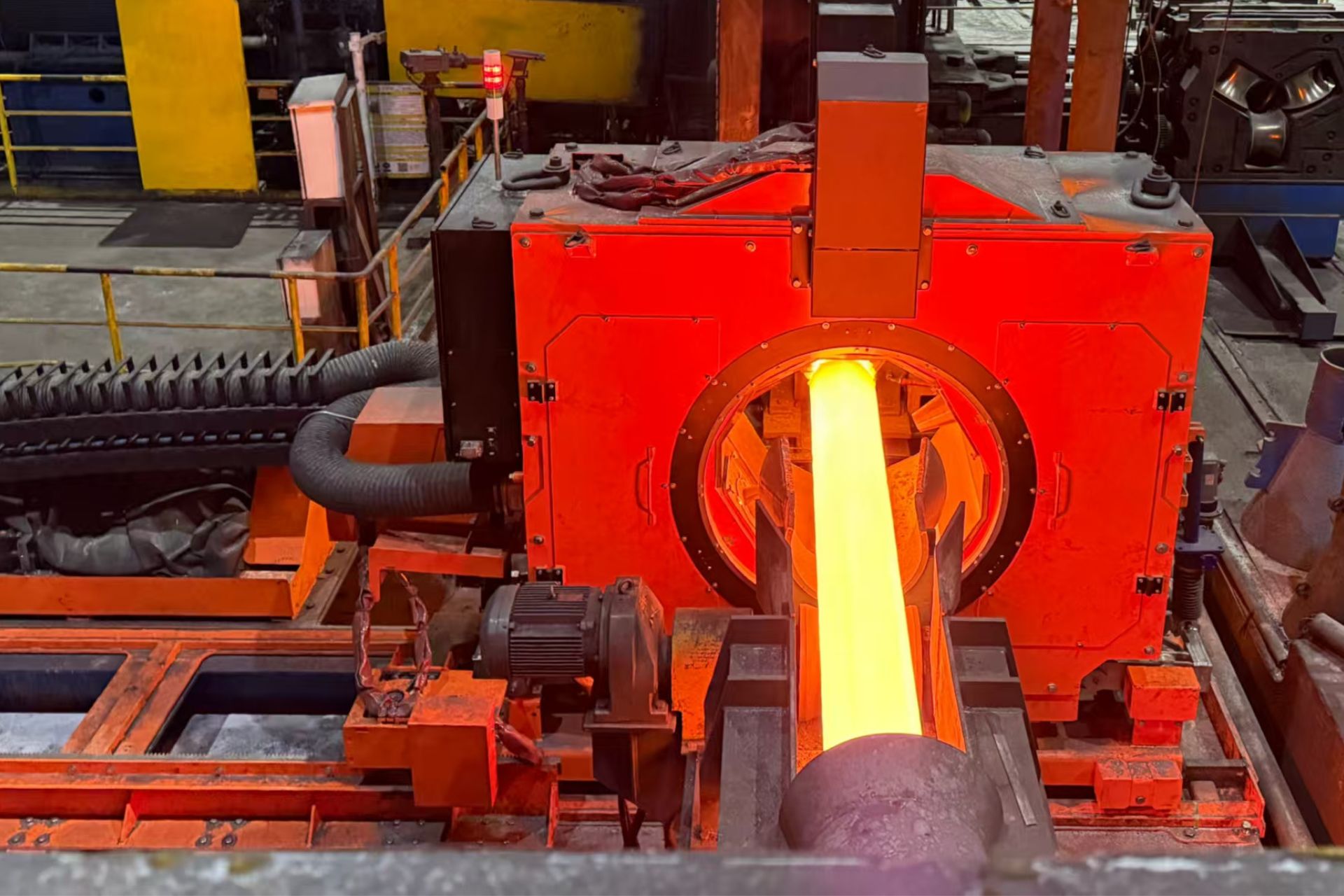

From billet piercing to cooling bed

With its laser ultrasonic core technology, Lut 2.0 is not affected by tube motion or by a mandrel. What’s more, since it’s compatible with any tube diameter and heavy wall tubes, it can be installed at any step in the manufacturing process. All this gives operators information that is simply not available with traditional radiometric gauging technologies.

Proven reliability

With a proven industrial availability of over 98%, the Lut 2.0 is the process monitoring gauge you can trust. And its rugged reliability is all due to Tecnar’s proprietary-designed, high-powered diode pumped Marathon™ Laser at its core.

Integrated outer diameter gauge

The Lut gauge measures the outer diameter at the same location as the wall-thickness inspection, providing a complete view of pipe geometry along its length during production. The combined data enables early identification of out-of-shape conditions, such as overfilling or underfilling, and supports stable process control.

No gamma ray

The Lut 2.0 doesn’t produce nor use any harmful radiation, making it a safe and environmentally friendly alternative to radiometric gauges.

Industry 4.0 ready

The Lut 2.0 comes with a web-based interface, flexible data architecture, and advanced analytical tools, ensuring easy integration with existing plant’s IT infrastructure and readiness with industry 4.0 standard.

Ongoing support and warranty

Tecnar takes pride in offering the best manufacturing/engineering warranty and support in the business so you can rely on Lut 2.0 for years to come.

But don’t just take our word for it… take it from our customers.

Interested in getting the most out of your hot seamless pipe line?

Leave your details so our experts can contact you.

Our team will answer all your questions and suggest the best solution for your needs.