Typically, the Lut 2.0 installation takes four (4) weeks from erection to final factory acceptance tests. With appropriate site preparation, equipment installation and the interconnections between various units take less than five days. On the following week of installation, functional tests are conducted and the Lut probe(s) is/are put online for the first time. The next two weeks (weeks 3 and 4) are dedicated to the online validation of gauge performances, calibrations, acceptance and operator training, thus completing the installation process.

Minimal preparation is required prior to the arrival of Tecnar’s installation team. The customer should complete the groundwork for the installation of the Lut probe support structure, prepare the equipment room, indicate where the cabinets will be installed and have electrical power and automation signals ready. A well-prepared installation site makes the Lut erection fast and efficient, allowing Tecnar’s specialist to complete commissioning in a timely fashion.

With the Lut flat-rate service plan, user maintenance is limited to a few simple tasks: yearly cooling fluid and filter replacement, detection laser flashlamp replacement, typically every month, and a weekly visual inspection of the air supply filter and probe output window.

The accuracy of the Lut wall thickness measurements, which are based on ultrasonic pulse time of flight, does not drift over time. No periodic wall thickness calibration or zeroing are required.

Tecnar offers free remote customer support to all Lut 2.0 users. Should a customer encounter an issue, our dedicated service team supports troubleshooting efforts to get the gauge back online as efficiently as possible. On the rare occasion when problems cannot be solved remotely, our service specialists are quickly dispatched to resolve the situation on site.

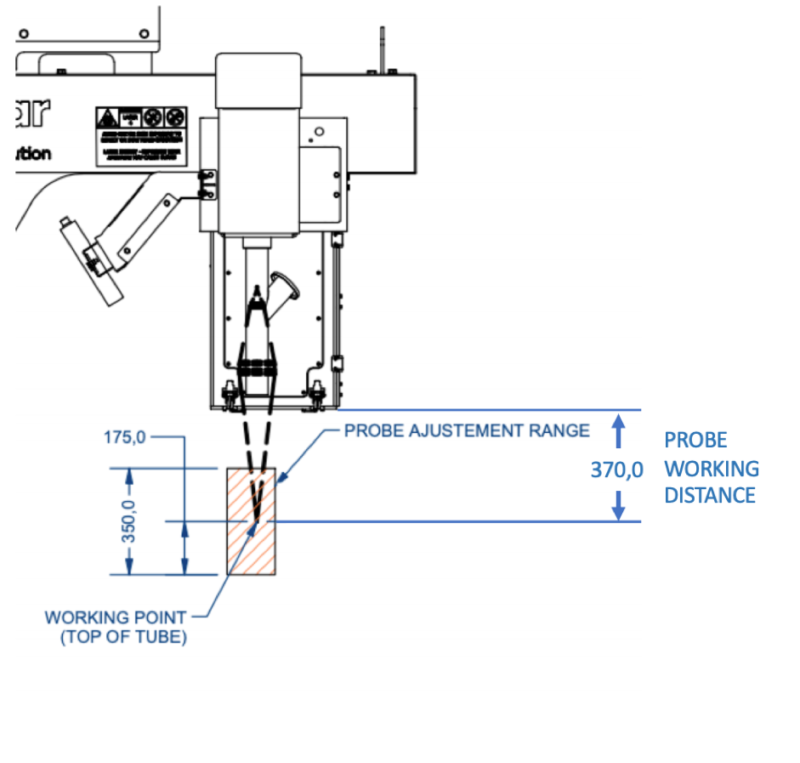

The Lut 2.0 working distance is fixed by the optical system used in the probe. The position of the Lut probe with respect to the surface of the moving tube is automatically adjusted based on the nominal tube diameter received from the factory level 2. Furthermore, the large optical depth of field (±25mm) of the Lut 2.0 allows it to accommodate significant variation in the tube position (due to tube motion or vibrations) without affecting thickness measurements or requiring adjustments of the probe’s position. The figure shows a schematic drawing of the Lut 2.0 SPF with its standard working distance of 370 mm and a range of 350 mm for adjusting to different tube outer diameter.

The Lut 2.0 uses an industrial blower (high-volume low-pressure) to keep its probe output window clean. The blower provides up to 2000m3/hour of clean filtered air. The blower may be located up to 20 metres away from the probe. It is recommended to connect the blower inlet to a duct that takes air from outside the plant in order to extend the air filter’s useful life span.

The Lut 2.0 has several features to boost plant production with increased yield and decreased costs. . Estimation of a return on investment for a specific plant involves evaluating several parameters, such as yearly tonnage requiring remake due to eccentricity, yearly tonnage of out-of-specification products, tube sampling and processing costs, loss of production time due to waiting for sampling results, yearly tonnage of scrap tubing during size changes of a production batch, among others. Each case is different and has its own specificities. Our experts are available to meet with you to evaluate the impact of having a Lut 2.0 on your production line.

We might be able to give you a ballpark figure based on Tecnar’s experience with different mills under different conditions. Assuming a 100,000 ton/year, by reducing the downtime after a size change (immediate wall profile for each tube), by tightening the wall tolerance (making longer valuable tube) and minimizing the number of out-of-spec. products (tracking the evaluation of production parameters), a single Lut 2.0 will save your plant up to $570,000 USD per year.

Unfortunately, we all know that in a tube mill, the product does not always go where we intended it to go, so in the past, Lut probes and structures have been hit by wandering hot tubes. Tecnar has designed several features to reduce the impact of a collision on the repair cost of the system.

For the Lut 2.0 SPF, the jib crane support structure has been designed to allow for maximum clearance of a stray tube. The large working distance leaves a safe distance between the hot product and the probe. In addition, the structure is mounted with rubber support that will detach in case of impact, reducing the amount of kinetic energy transferred to the system.

For the Lut 2.0 TPS, DPS and SPP, the support structure has been designed with a large aperture: 1 m, to allow clearance for any stray tubes. In case of impact, the rugged structure is mounted on a rubber support that will detach in case of impact, minimizing the possible damage to the structure.