Daye Special Steel

Daye Special Steel, China's “cradle of steel”, is located in Huangshi City, Hubei Province, the capital of mining and metallurgy and a major manufacturing region in China. Daye has a capacity of 8.3 million tons of steel and special steel. Among other things, it produces a wide variety of alloys and a wide range of high-end thick wall seamless steel pipes up to 100 mm wall thick.

Pushing boundaries

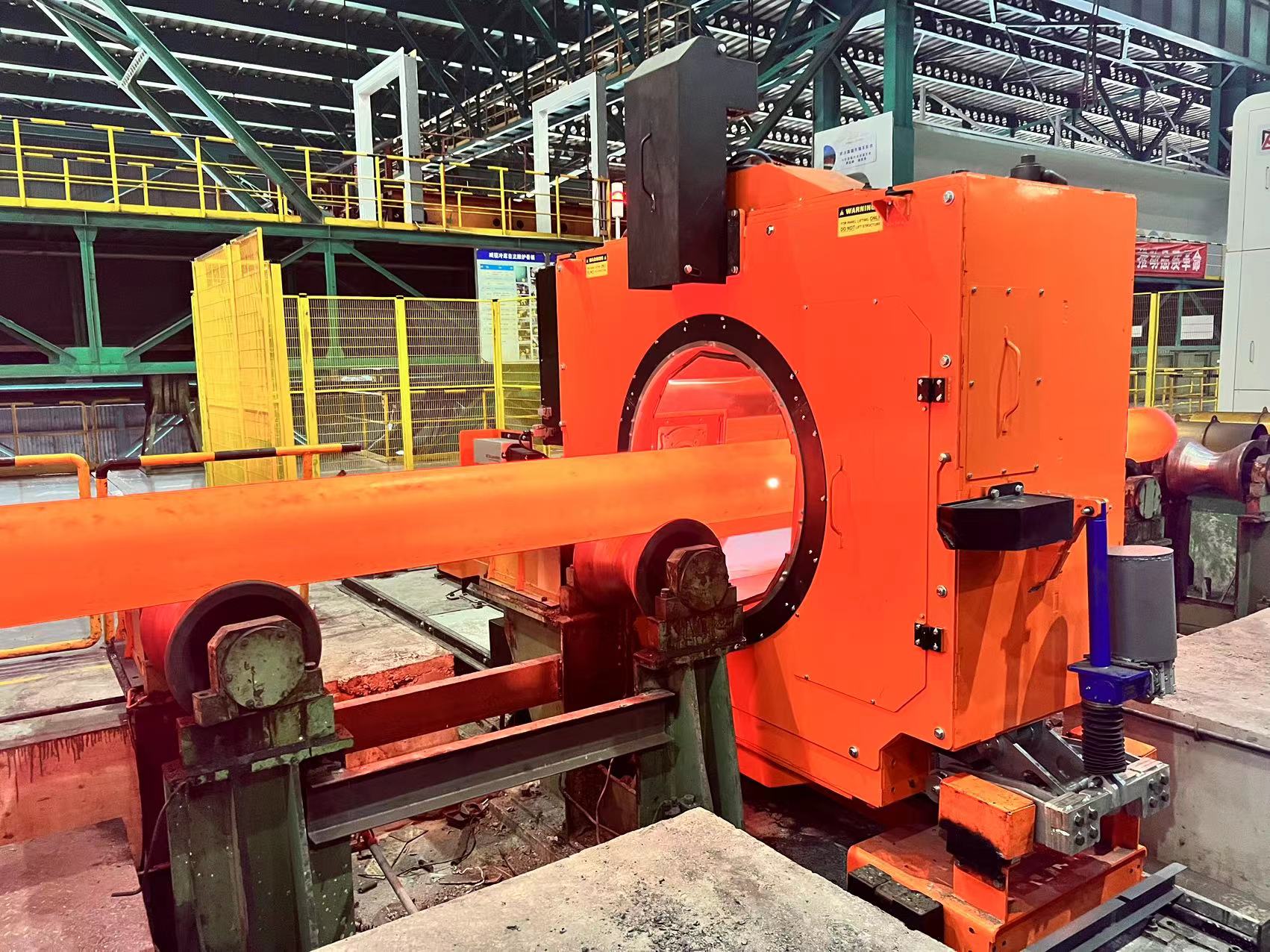

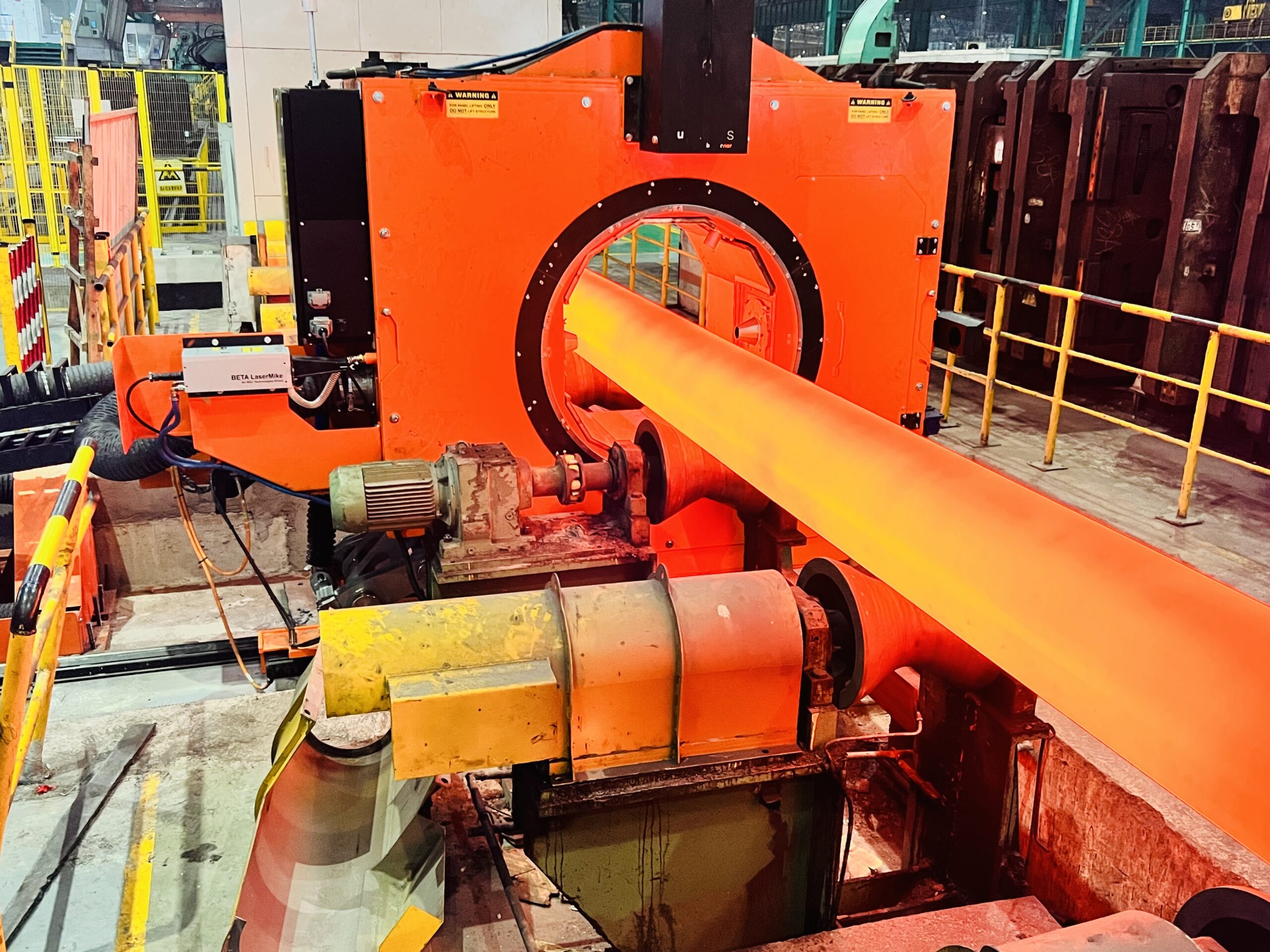

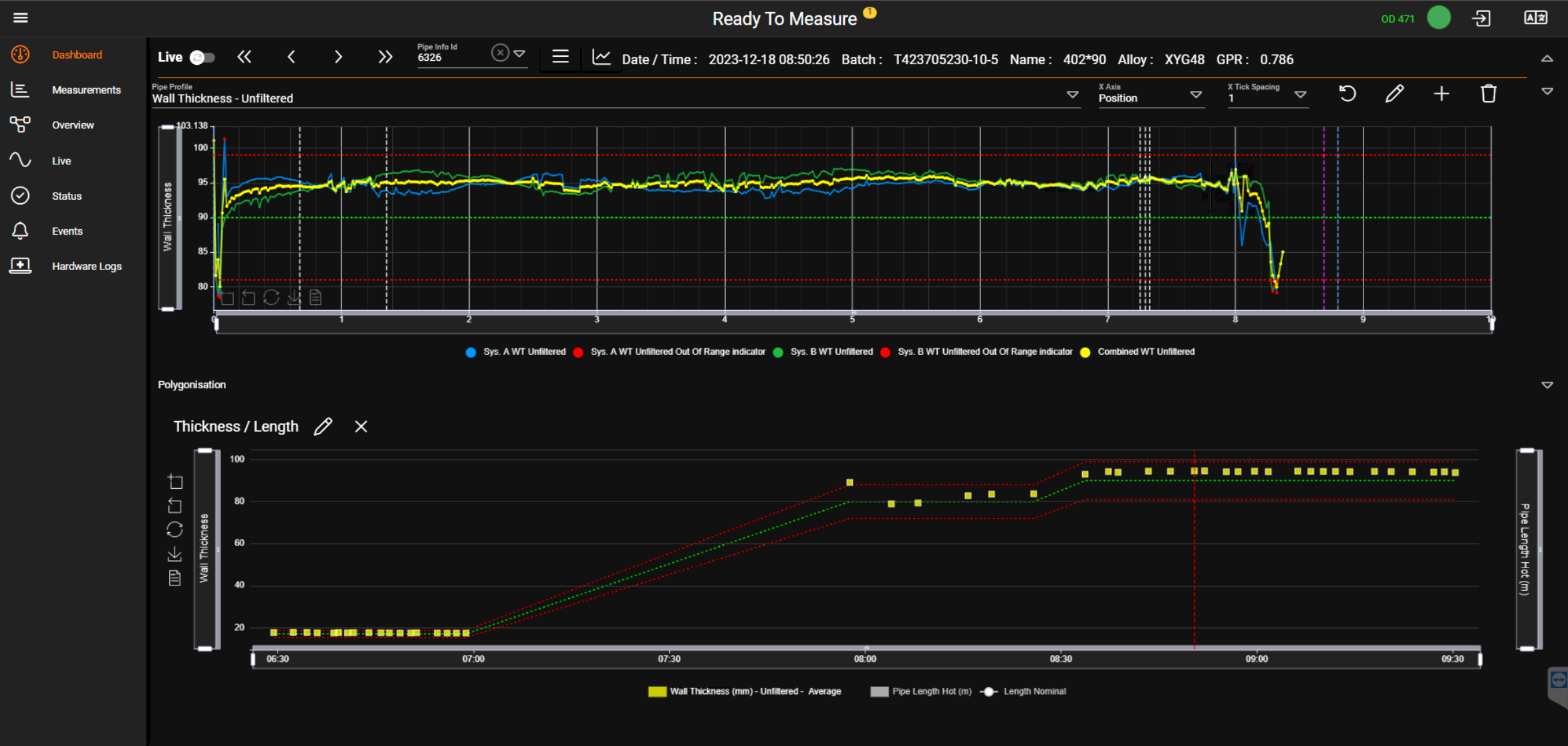

Overcoming the challenges of producing exceptionally heavy tubes requires a strategic approach. Daye has strategically invested in Tecnar’s Lut system to enhance productivity and minimize material waste. The formidable task of measuring wall thickness, especially beyond 50 mm, made it extremely difficult to choose the right online thickness gauge. Tecnar embraced the challenge and brilliantly succeeded with the Lut 2.0. Its groundbreaking online wall thickness measurement capability can extend up to 90 mm for a wide range of steel grade alloys at the output of the sizing mill.

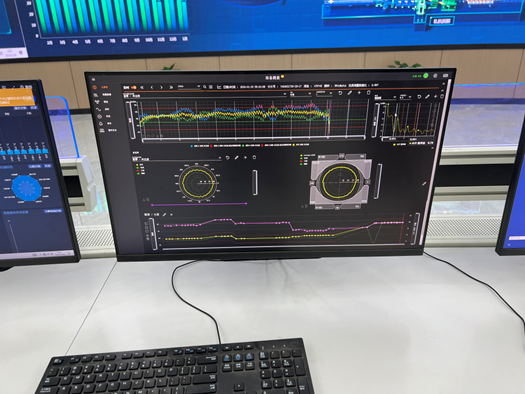

Daye and Tecnar engineers, working closely together, focussed on optimizing data collection, analysis, and presentation. This ongoing collaboration culminated in user-friendly tools tailored to mill operators, streamlining operations and enhancing overall production efficiency.

Flexible operation mode

Lut 2.0 has two modes: fixed or scanning — to focus on difference sources of eccentricity

Material loss mitigation

True measurements to keep pipe within specifications

High accuracy

Hot tube characteristics at every stage, from furnace to cooling bed

Game-changing information

Lut 2.0 has the flexibility to work in a fixed or scanning mode. It identifies and displays specific tube characteristics from every stage of production, from heating to the sizing mill, including piercing and elongation. It can even detect the distinctive Assel mill signature. This information was not available before the Lut 2.0, making it a great tool to optimize process and product quality.

Talk to our expert today

Leave your details so our experts can contact you. Our team will answer all your questions and suggest the best solution for your needs.