World leader in industrial laser ultrasonics

With over 20 years of expertise designing, manufacturing and implementing sensors in the toughest industrial environments possible, no one can beat us!

Talk to an expertDeveloped specifically for tube mills

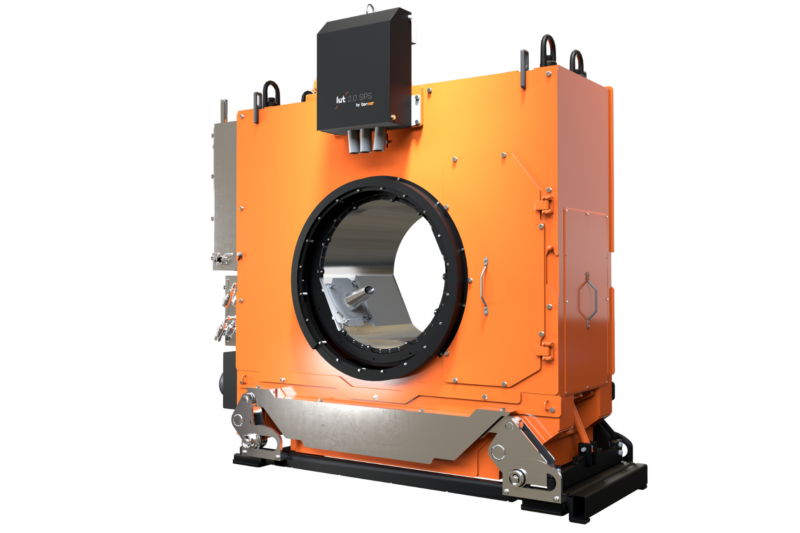

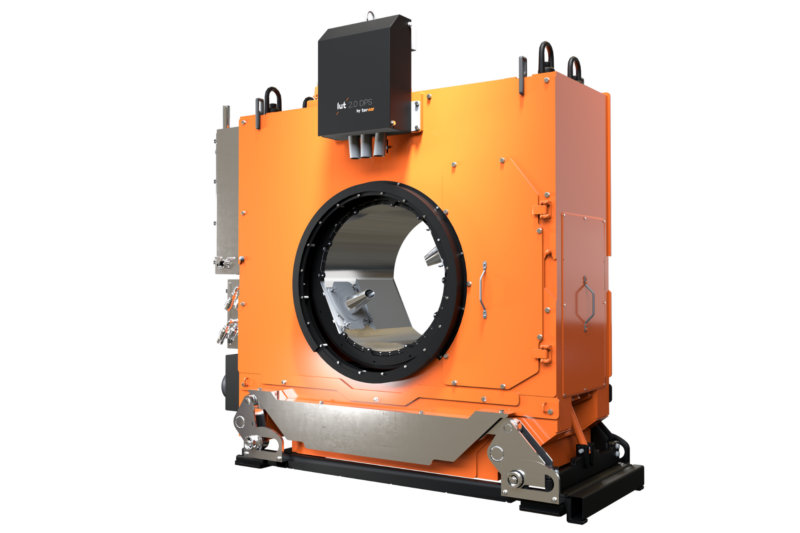

Specialized integrated hardware

To achieve bulletproof reliability for tube mills hash environment, Tecnar has developed its own laser ultrasonic core units by leveraging the experience of over 25 Lut 1.0 gauges in more than 15 seamless tube mills around the globe. The Lut 2.0 is the next step in seamless tube wall thickness monitoring.

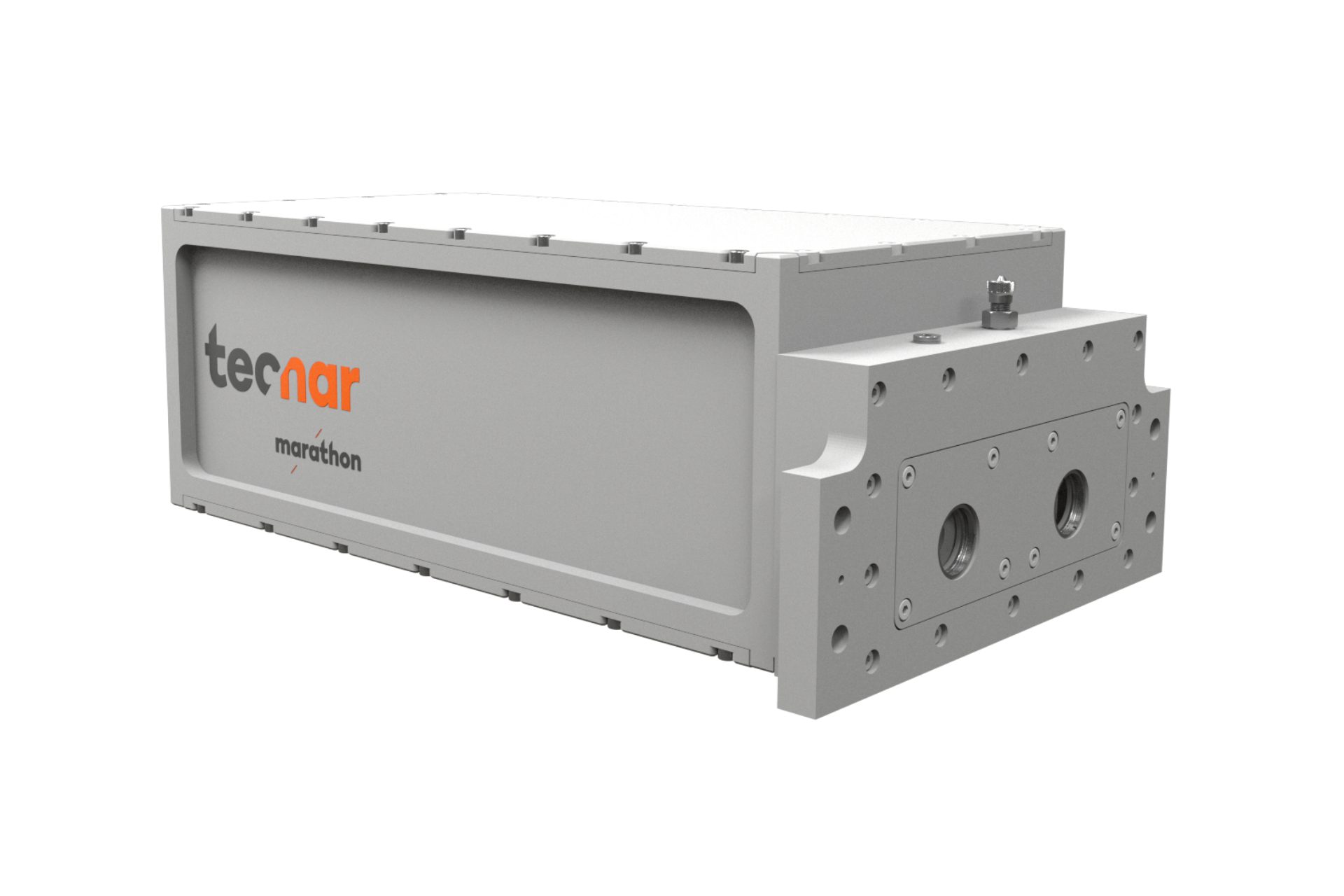

Marathon™ generation laser

The generation laser is the hammer that generates the ultrasonic probing pulse. Located directly over the tube on the production line, it must be extremely rugged to withstand the harsh environment. When Tecnar wasn’t satisfied with the performance and reliability of commercially available lasers, we developed the first and only high-power laser dedicated to seamless tube inspection.

The Marathon is a diode-based, high-power, q-switched laser that delivers a fast firing rate with unmatched reliability. It allows the Lut 2.0 to inspect tubes over 40mm in thickness up to 300 times per second. Since it’s based on diodes rather than flashlamps, the Marathon doesn’t require any periodic maintenance. From start to finish, the Marathon truly goes the distance for years of trouble-free operation.

- Firing rate: 100Hz

- Power per pulse: 300mJ

- Pulse width: >8ns

- Diode lifespan: >6G shots

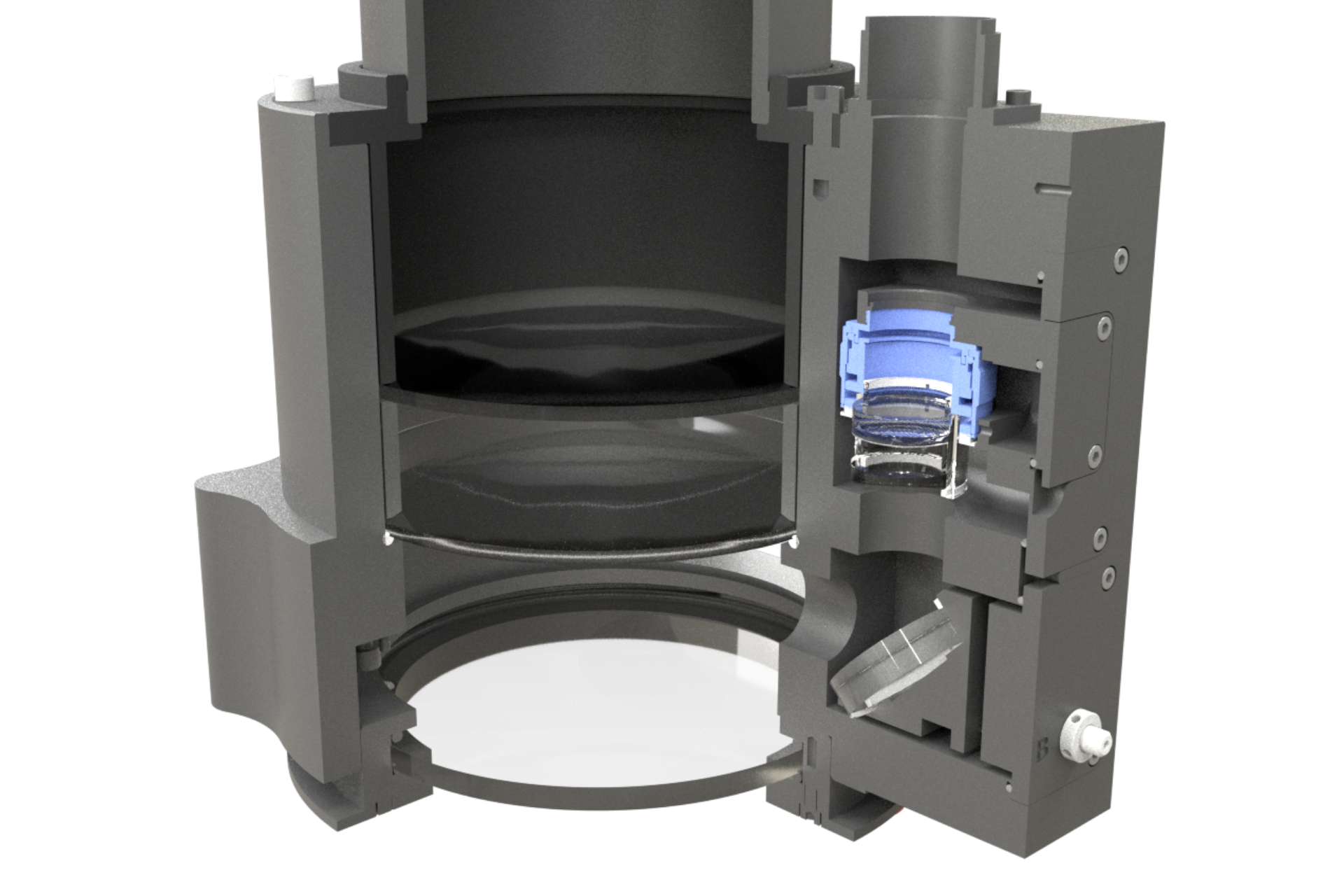

PDL™ detection laser

Tecnar is the world leader in industrial laser ultrasonics for one solid reason: the PDL, our proprietary, high-power, pulsed-detection laser. To this day, the PDL is the only laser of its kind in the world.

The PDL is one hundred times more powerful than typical detection lasers, giving the Lut 2.0 the largest depth of field (±25mm) in the industry. That means that the tube can bounce significantly without affecting the accuracy of the gauge. It also provides a long working distance so the probe can operate safely over 350mm away from the tube, minimizing the risk of collision.

- Firing rate: 100Hz

- Peak power: >750W

- Pulse width: >175µs

- Diode lifetime: >10G shots

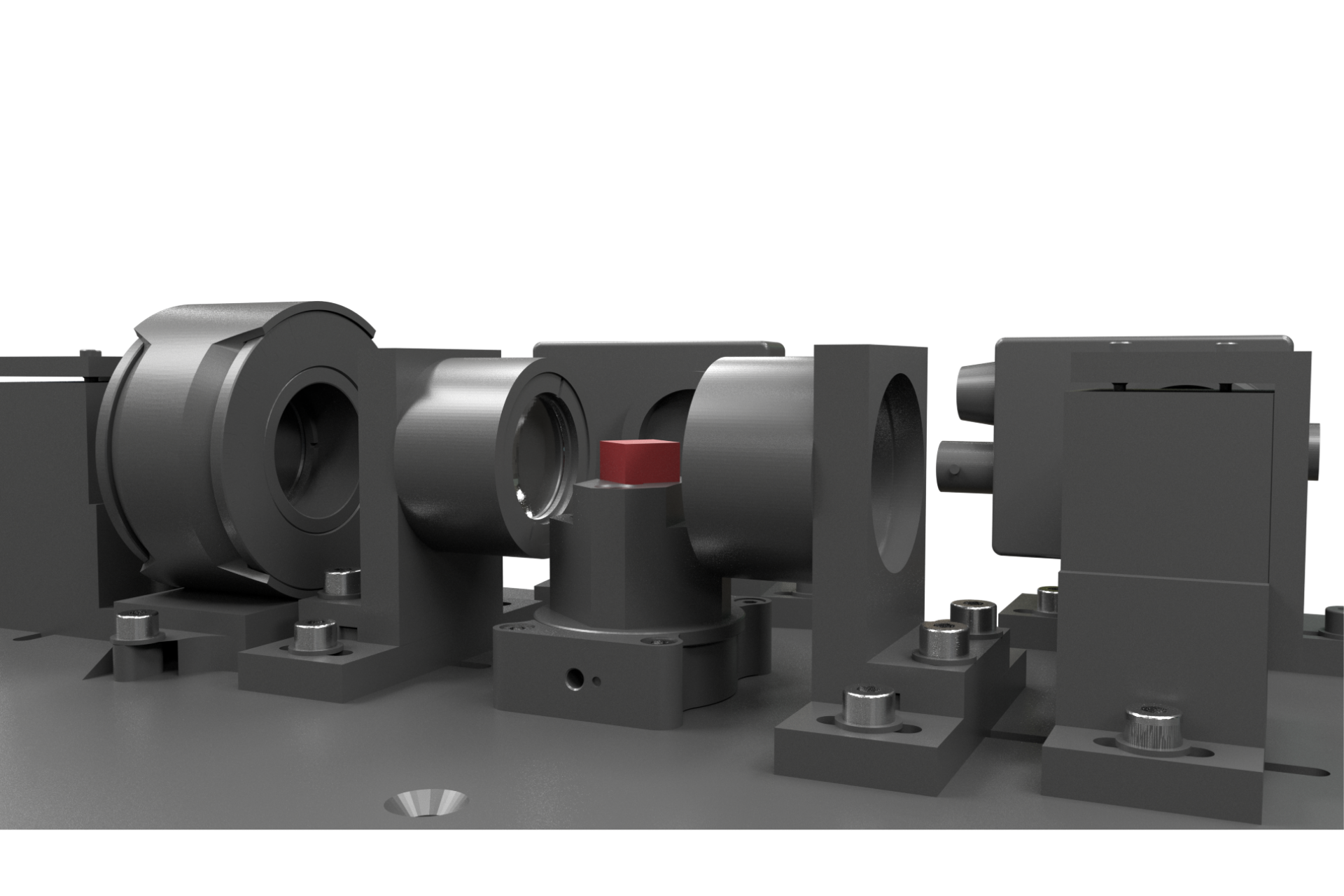

TWM™ ultrasonic detector

Laser ultrasonic detectors often require active stabilization to compensate for environmental vibrations and operate properly. These detectors are well suited for lab applications but not effective in harsh industrial environments.

The Lut 2.0 TWM detector, based on two-wave mixing technology, does not require active stabilization. It is naturally immune to ambient vibrations, making it especially well suited for the rough environment of seamless tube mills.

Durabeam™

The performance and lifetime of high-power optical systems are severely affected by dust and humidity. To tackle this challenge, Tecnar developed the Durabeam, a novel design concept for industrial optical systems. Durabeam technology isolates all optical components from the environment while maintaining serviceability in the field, ensuring long-term reliability and low-maintenance costs for the Lut 2.0 inspection probe.

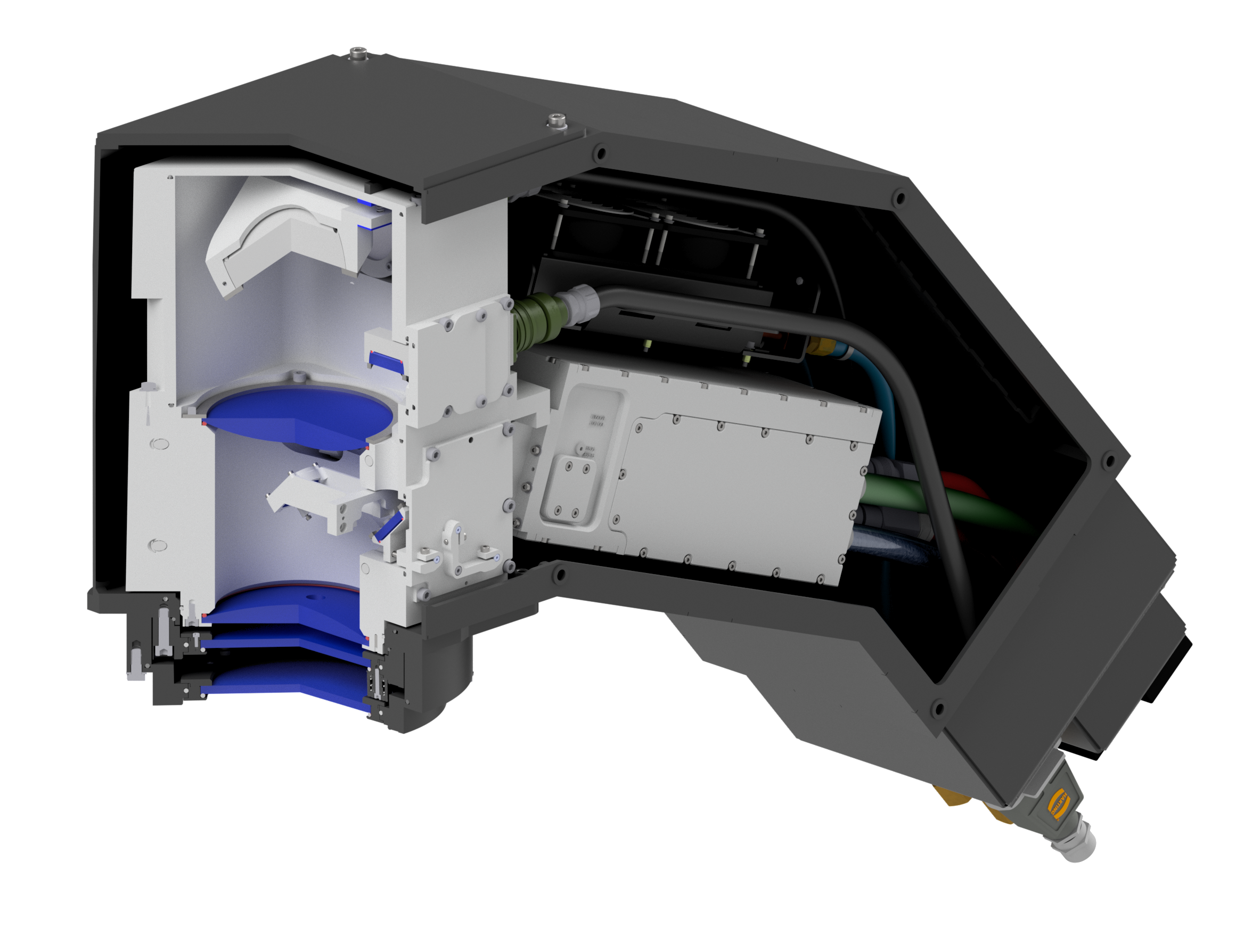

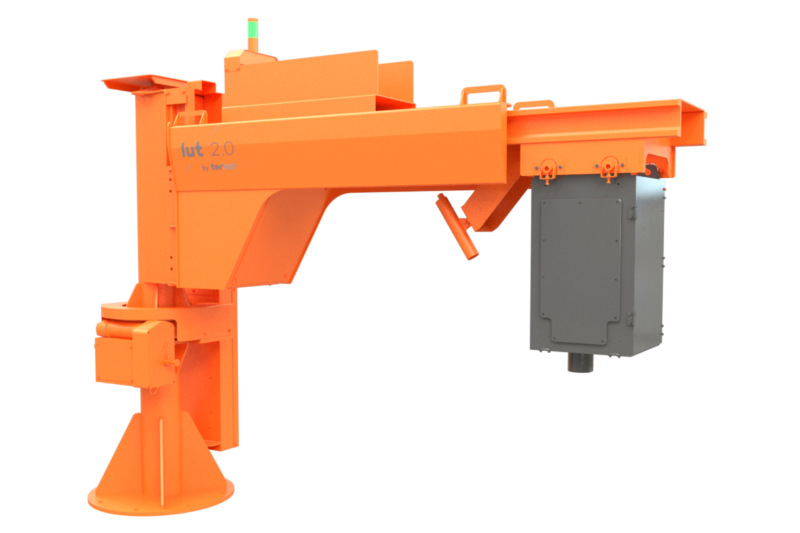

Inspection probe

The Lut 2.0 inspection probe is installed directly over the tube on the production line and must stand up to the harshest conditions in the mill. This rugged, thermally insulated and water-cooled inspection probe can withstand the worst conditions in a seamless pipe mill. What’s more, it’s resistant to vibration, heat, water, dust and oil to keep working no matter what.

Small footprint

Finding space to squeeze in new equipment on a hot seamless tube line is always a challenge. To address this issue, only the Lut compact positioning device, equipped with an inspection probe, is installed in close proximity to the mill. The other components, such as the electronics and support systems, are installed in a clean room up to 60m/200ft. away from the production line.

Discover the different Lut 2.0 configurations

Talk to our expert today

Leave your details so our experts can contact you. Our team will answer all your questions and suggest the best solution for your needs.