All-in-one wall thickness and OD gauges for hot tube and pipe mills

Tecnar has over 20 years of experience delivering sensors to hot seamless and welded tube and pipe mills. Engineered for accuracy and durability, the Lut 2.0 measures wall thickness and outer diameter in a dependable, low-maintenance system.

Talk to an expertWhy get an inline gauge?

The Lut 2.0 gauge continuously monitors production and helps operators ensure that the mill is operating at full capacity.

- Avoid loss when rolling a high-tolerance short production lot in which every piece needs to be perfect

- Monitor slow drifts in the tube characteristics during long production runs caused by wear in the mill.

Reduce mill set-up time by 180h/year

See the impact of rolling parameter changes as soon as the first tube leaves the mill. Quickly attain tolerance, especially during size changes.

Increase yield up to 5%

By constantly monitoring the tube dimensions, operators can track tool wear and slow process drift as they develop, helping them to react before the tubes are out of tolerance.

Thickness variation <7%

Set tighter tolerance on wall thickness and reduce end length and eccentricity. Use less material and roll better-quality tubes.

Reduce losses >10,000t/year

Use the Lut 2.0 data to increase overall yield by minimizing the length of the heavy ends.

Real-time monitoring

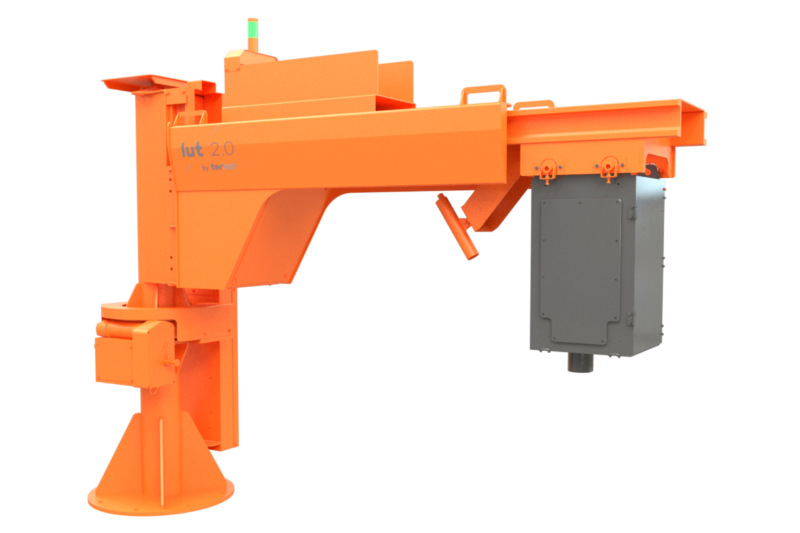

The Lut 2.0 fully automated measurement sequence easily integrates into your existing automation system for a fully seamless operation.

Safer work environment

The Lut 2.0 automates tube dimension measurements so operators can work more safely and efficiently.

Discover the innovations behind the Lut 2.0

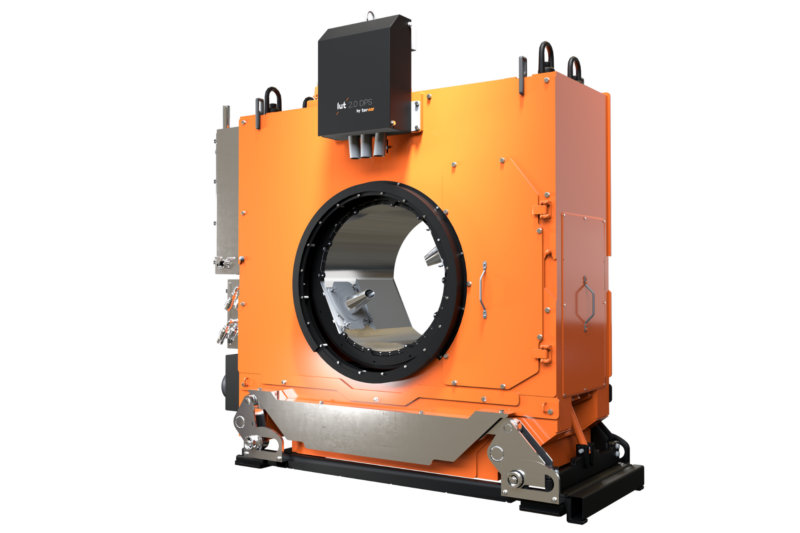

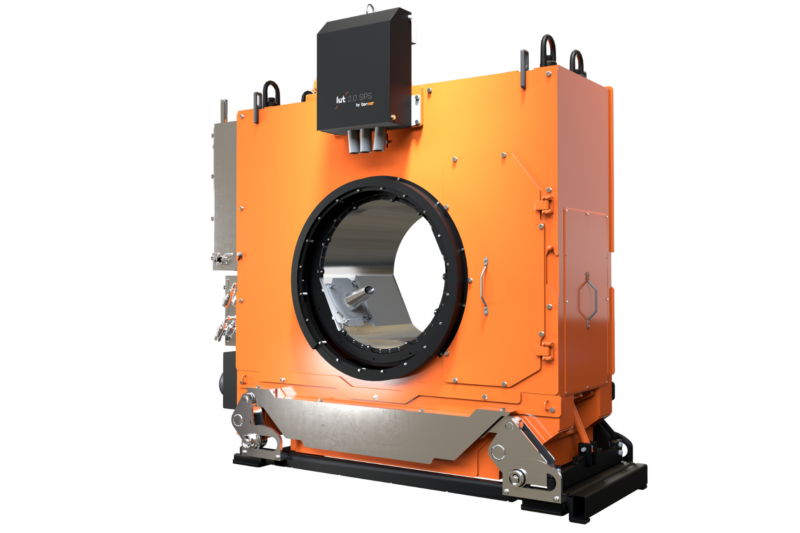

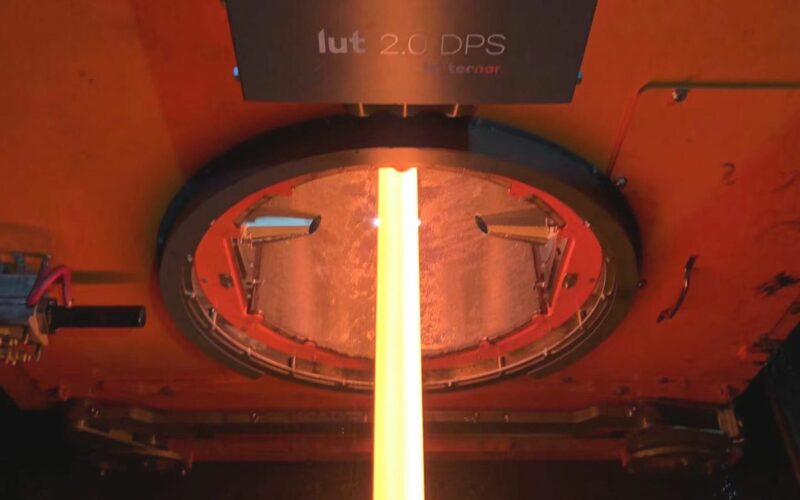

The Lut is the first technology to provide true online wall thickness measurement with micron-level accuracy. With the integration of an outer diameter gauge, it now delivers the complete dimensional profile of tube and pipe during hot production.

Designed for versatility, it is the only gauge that fully characterizes eccentricity and can be deployed at any location along a hot tube and pipe mill production line.

Laser ultrasonics technology

The only technique to provide true, direct wall thickness measurements.

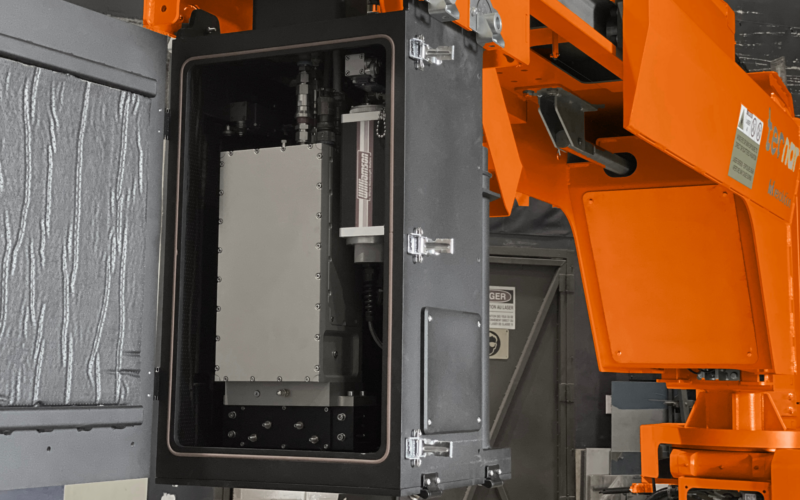

Proprietary hardware

The Lut 2.0 core units are built around Tecnar’s proprietary designs and engineered to achieve one goal: bulletproof reliability.

User friendly software

The Lut 2.0 is equipped with a web-based user interface and a SQL database that can be accessed from anywhere in the plant.

Meet our product

The Lut 2.0 is offered in four different configurations to give you the best features for your application:

Ongoing support and warranty

Tecnar takes pride in offering the best manufacturing/engineering warranty and support in the business so you can rely on Lut 2.0 for years to come.

But don’t just take our word for it… take it from our customers.

About Tecnar

Tecnar knows that better process control means increased productivity. That’s why your productivity is at the heart of everything we do. Tecnar designs and develops advanced sensors for industrial process monitoring and control.

Founded in 1989 as a spin-off from Canada’s National Research Council, Tecnar has since diversified into four highly specialized product lines: automated pressure pipe welding, thermal and cold spray sensors, non-contact laser ultrasonic sensors and laser-induced breakdown spectroscopy (LIBS) sensors.

Ready to increase plant yield by 5%

Contact us to learn how to leverage the data from the Lut 2.0 and get a return on your investment in less than 2 years.